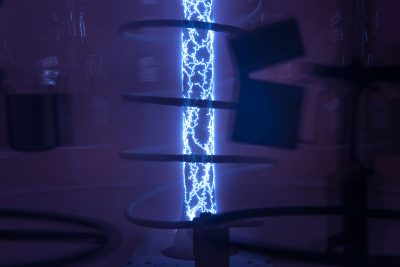

At Tanury, we blend artistry and science to deliver superior quality. There is no better example of this than our physical vapor deposition (PVD) service. In 1994, Tanury introduced PVD to the decorative coating market place. Using a unique dry-vacuum process, parts are coated with materials such as ultra-hard zirconium or titanium nitride.

Physical Vapor Deposition is typically used for high-wear applications and in any industry where the visual and functional performance of an item can be enhanced with a durable decorative coating. For example, PVD coatings are commonly used in automotive, plumbing, hardware manufacturing, medical, and electronic applications as well as for large and multi-dimensional parts.

At Tanury, we take the Physical Vapor Deposition process to a completely new level with the widest assortment of color options. We help our customers expand and improve their product base and bring innovative new finishes to market to remain competitive. Partnering with Brown University, the State of Rhode Island, and the National Science Foundation, we developed decorative in–line coating, where the deposition process always remains under vacuum, creating a fast cycle system. This system both saves time and provides higher-quality results.